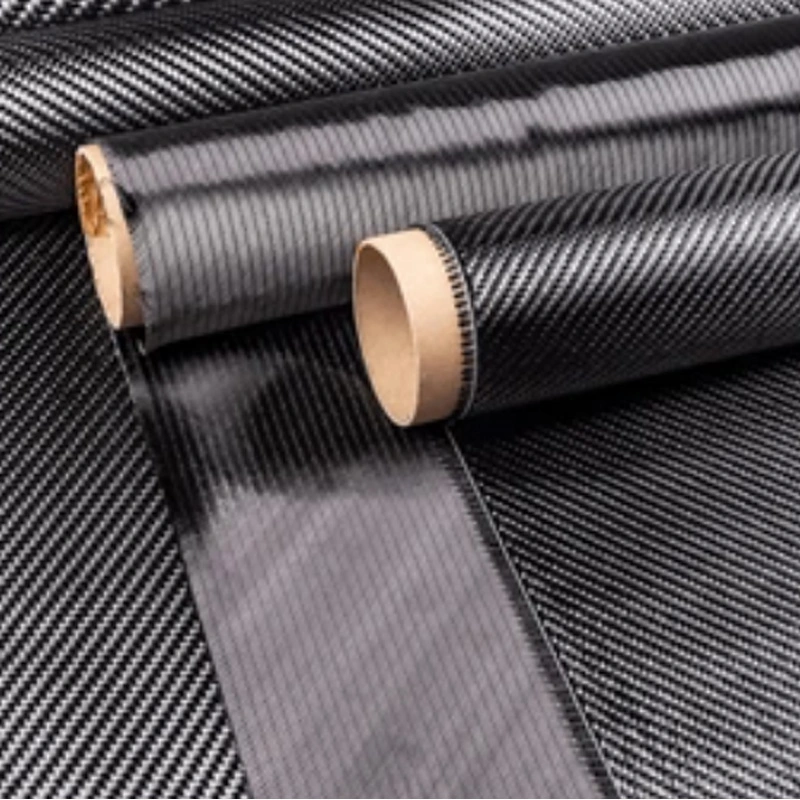

How Alumina Continuous Fibers Are Made

Alumina continuous fiber, with alumina and silica as its main components, is prepared by the "sol-gel" process. It can be used in high-temperature environments above 1000°C for a long time.

Sol-Gel Precursor: Aluminum salts dissolved in water, spun into green fibers.

Heat Treatment: Fired up to 1400°C to convert to pure α-Al2O3.

Post-Processing: Sized for weaving or chopped for composites.